Multiscale Thermal Fluids Laboratory (MTFL)

|

|

About MTFL

AT MTFL, our primary focus is on addressing thermo-fluids challenges across various applications. Our research efforts encompass a diverse range of topics, including capillary-scale multiphase flow, transport phenomena in porous media, droplet dynamics, and the evaluation of hydrodynamic and thermal performance in additively manufactured heat exchangers, heat sinks, and flow channels. At MTFL, we provide valuable training and supervision to both undergraduate and graduate students, enabling them to actively engage in research activities within the lab. Through hands-on involvement in our projects, students gain practical experience and develop their research skills, contributing to advancements in the field of thermo-fluids. Research

Transport phenomena in proton exchange membrane (PEM) fuel cell

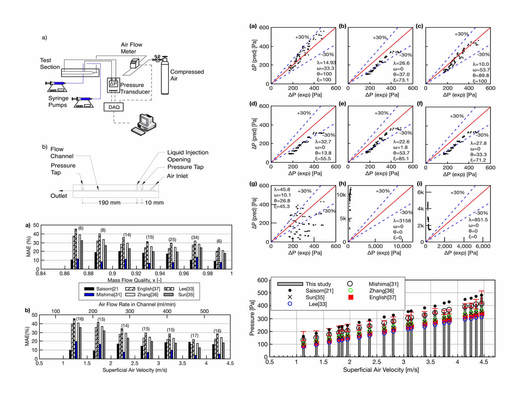

Liquid water transport in PEM fuel cell flow channels has been studied in an ex-situ setup. Particularly, liquid water droplet detachment from the surface of the gas diffusion layer (GDL) has been investigated under different gas flow rates and different PTFE content in GDL. Air and hydrogen gases were supplied in flow channel to represent liquid water droplet detachment in cathode and anode of the PEM fuel cell, respectively. Click here to read the journal article. Capillary-scale water transport through porous media

Water transport through porous media of PEM fuel cell is a capillary-scale transport phenomena that has been investigated. Liquid water breakthrough pressures have been measured for GDLs with different thicknesses and different PTFE contents. Liquid water pressure signature through porous layer has been studied in details. Click here to read the journal article. In-plane microstructure of PEM fuel cell porous media

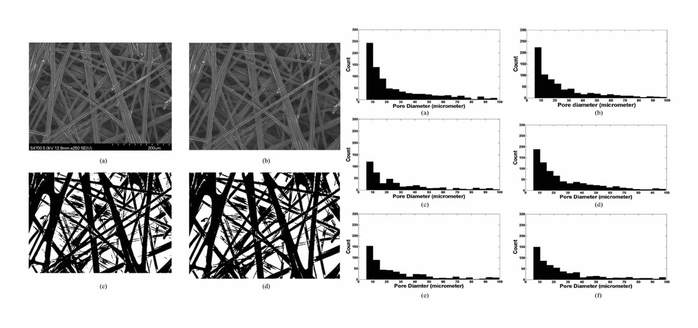

SEM images were taken from surface of GDL samples and were analyzed through image processing techniques. Important information such as pore roundness distribution, pore roundness distribution, and mean pore diameter were calculated. The data obtained in this study can be utilized in modeling water transport through the porous structure of GDL. It was observed that the mean pore diameter of Toray carbon paper does not change with its thickness and PTFE content. Mean pore diameter for Toray carbon papers was calculated to be around 26µm, regardless of their thicknesses and PTFE content. Finally, the heterogeneous in-plane PTFE distribution on the GDL surface was observed to have no effect on the mean pore diameter of GDLs. Click here to read the journal article.

Energy conversion and storage

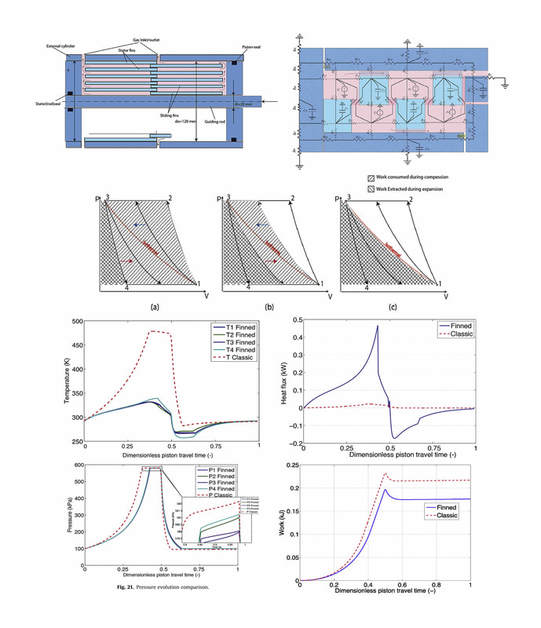

In this study, a new finned piston compressor that is characterized by increased heat transfer area and coefficient has been designed, analyzed, manufactured and experimentally tested. Results show that the heat transfer along one cycle has increased in the finned compressor by 32 times compared to a classic piston compressor. In addition, although the volumetric efficiency decreased slightly in the finned compressor (8%), the exergetic efficiency was observed to increase from 55.1% in a classic piston to 78.4% in the finned piston. Click here to read the journal article. Enhanced water removal from PEM fuel cell flow channels

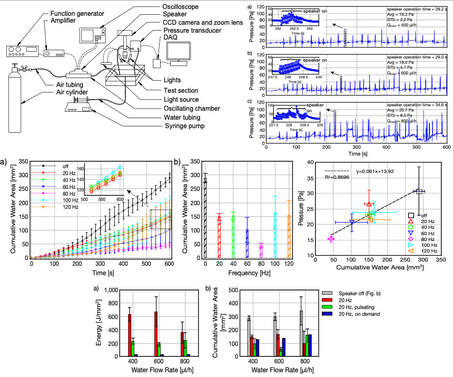

In this study, an enhanced liquid water removal scheme from an ex-situ PEM fuel cell flow channel is investigated by superimposing acoustic pressure waves on air flow prior to entering into the flow channel. Acoustic pressure waves at different frequencies were superimposed on air flow and water accumulation as well as liquid-gas two-phase flow pressure drop were evaluated during experiments. Acoustic pressure waves in the form of sine functions and at different frequencies between 20 and 120 Hz were superimposed on air flow. The lowest water accumulation within the flow channel was obtained when acoustic pressure waves were superimposed at 80 Hz. This frequency is close to natural frequency of water droplets at the size of droplets formed within the flow channel and therefore, it is speculated that droplets are expelled due to resonance. In addition, water removal for three different superimposition schemes were evaluated in this study; (i) continuous superimposition, (ii) pulsating on and off, and (iii) on demand. The on demand superimposition represents superimposing acoustic pressure waves when speaker was generally off and was turned on once a droplet was formed within the flow channel. Comparing speaker energy for different modes indicates that the latter is the most efficient superimposition scheme with respect to energy used in speaker to expel the same amount of water content. Click here to read the journal article. This video shows water removal from the flow channel of the test section. Three separate experiments were conducted to study the effect of superimposing acoustic pressure wave on water removal from the surface of the flow channel. The flow channel on left belongs to an experiment with no acoustic pressure wave being superimposed on air. The middle flow channel is when the acoustic pressure wave is applied with a pulsating mode (the speaker was on for 10 s and was off for 10 s). The flow channel on right belongs to an experiment when the speaker was continuously on. This video shows that superimposing acoustic pressure wave can expel water from the flow channel due to resonance that occurs at frequency close to natural frequency of water droplets (compare water content at the end of the video).

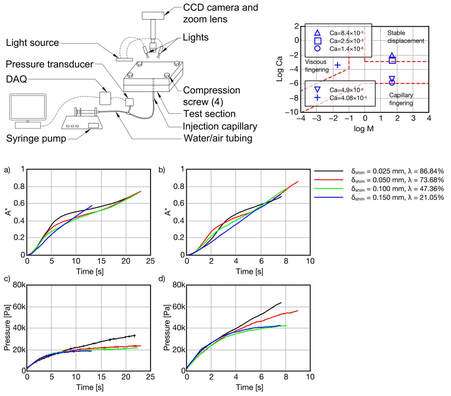

Drainage phase diagram in PEM fuel cell porous layer under compression

In this study, the drainage phase diagram of the PEM fuel cell porous layer, GDL, was investigated at different compressions. The stable displacement, capillary fingering, and viscous fingering flow regimes were evaluated in carbon paper and carbon cloth samples at four different compressions. While only capillary fingering is the subject of PEM fuel cell, obtaining data for the stable displacement and viscous fingering flow regimes can be beneficial for validating pore network models. In this study, liquid water or air percolation within the plane of the GDL was visualized with a CCD camera while the percolation pressure was measured with a pressure transducer. Images were analyzed to obtain the nondimensional wetted area which was defined as the area occupied by the wetting fluid to the GDL sample area. Click here to read the journal article. Applications of machine learning in PEM fuel cell two-phase flow

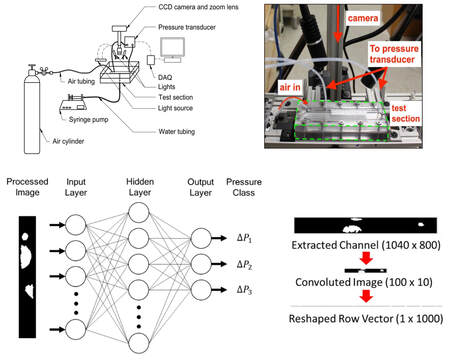

In this study a novel application of machine learning to quantify the liquid water accumulation in PEM fuel cell flow channel is introduced. To correlate liquid water distribution with a two-phase flow pressure drop, this work trains various machine learning models using images of water slugs in a flow channel to predict the pressure drop range. Images of two-phase flow were post-processed and used as input data to three machine learning models: Logistic Regression, Support Vector Machine and Artificial Neural Networks (ANN) to classify the images into three pressure classes: (i) pressure drop less than 15 Pa, (ii) pressure drop between 15 and 30 Pa, and (iii) pressure drop greater than 30 Pa. The performance comparison of machine learning models is reported using the confusion matrices and classification accuracy. ANN performed best for this application and resulted in 95% accuracy on both train and test datasets. This approach can be utilized to predict the pressure drop values in the flow channels of PEM fuel cells based on liquid water content distribution along the channel. Click here for the journal article. Force scaling comparison of two-phase flow in PEM fuel cells compression

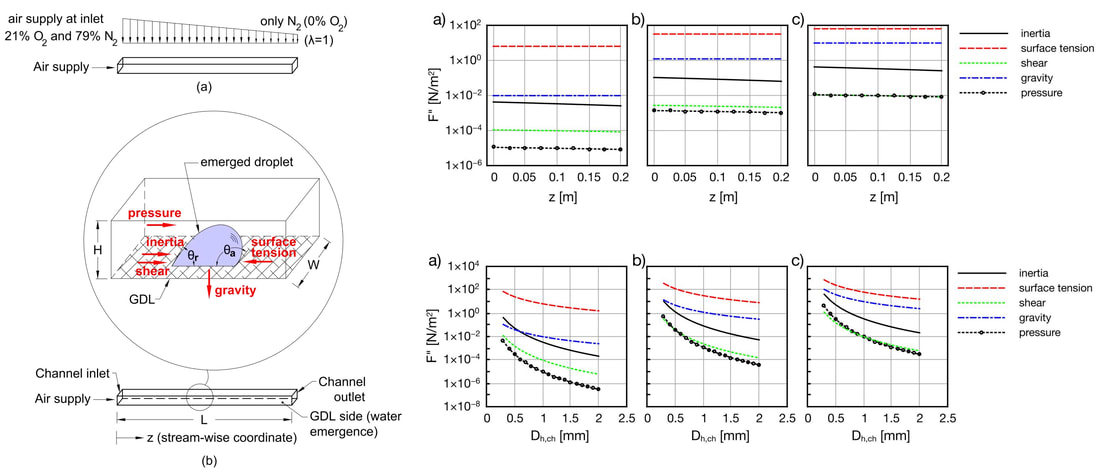

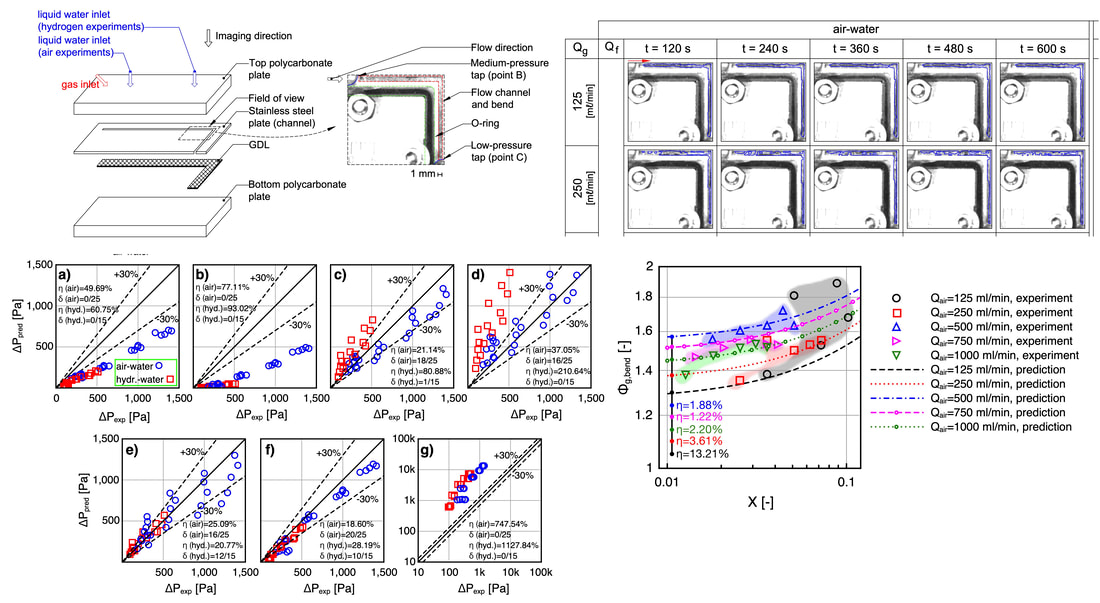

In this study, the governing forces on the liquid-gas two-phase flow in PEM fuel cell flow channels are compared analytically. The study compares the magnitude of the forces experienced by liquid water residing in the flow channel. In the analytical model, a 20-cm-long flow channel was analyzed and the forces were compared in the stream-wise direction of the channel. Results indicated the dominance of the surface tension forces over other forces applied in the channel. In fact the surface tension forces were observed to be three orders of magnitude greater than the gravitational effects, the second largest force scale for a droplet diameter of 0.1 mm. However, for larger droplets this difference becomes smaller. Three undergraduate ME students were involved in this research study. Click here to learn more about this study. Two-phase flow pressure drop in PEM fuel cell flow channel bends

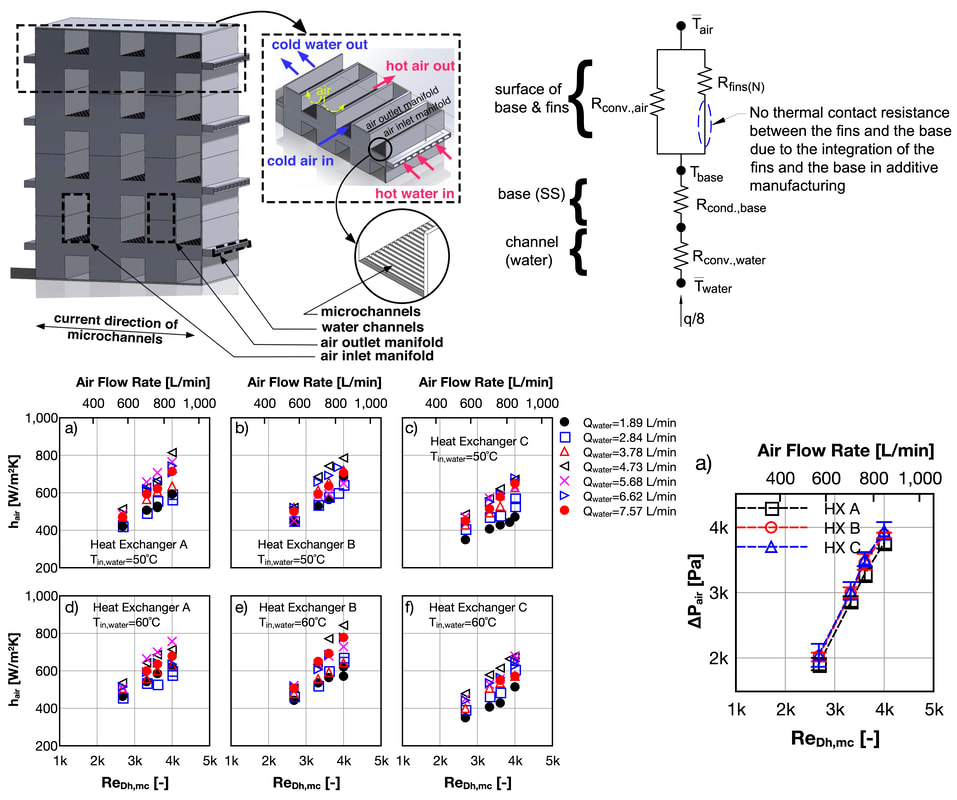

In this study, liquid-gas two-phase flow pressure drop across PEM fuel cells flow channel bends was studied. Experimental data were compared to some of the existing models that have been developed to predict the pressure drop across bends for larger channels. Results showed that existing models cannot properly predict the pressure drop in PEM fuel cell bends. A two-phase flow pressure drop model is developed based on the separate flow model. Results demonstrated that the new model can properly predict the pressure drop with a high accuracy. Click here to learn more about this study. Additively manufactured metallic heat exchanger

In this study, the hydrodynamic and thermal performance of additively manufactured heat exchangers were evaluated. Three manifold-microchannel heat exchangers were additively manufactured from stainless steel and tested experimentally. The overall size of the three heat exchangers was identical but their interior designs were slightly different. One of the benefits of AM technology is the integration of different components into one component. This is beneficial in heat exchanger as it eliminates thermal contact resistance in gaps. This study started as a senior design by Riccardo Clemente as a requirement of his BS degree in Mechanical Engineering and resulted in one journal paper and two peer-reviewed conference papers. Click here to learn more about this study. Gallery

Some of the experimental setups that have been developed at MTFL are presented below. This video shows a liquid water droplet sitting on the surface of the gas flow channel. Air is supplied in the channel and flows from left to right. Around 5 seconds into the video, acoustic pressure waves are superimposed on core gas flow at a frequency of 20 Hz. Acoustic pressure waves induce inertial forces in the droplet which deform the droplet in a rocking motion pattern. After one complete rocking motion cycle, the droplet detaches from the surface of the channel. The footage is captured by a high-speed camera at Multiscale Thermal Fluids Laboratory at Western New England University, located in Springfield, MA. The video is slowed down for 200x. This research was funded by NSF (CBET 2018150).

This video shows a water droplet sitting on the surface of the gas flow channel when air is supplied in the channel (from left to right) with a superficial velocity of 10.76 m/s. The video shows that the droplet undergoes an oscillatory trend in this condition. No external excitation (such as acoustic pressure waves) is superimposed on the core gas flow. This video is 10X slowed down. This research was funded by NSF (CBET 2018150).

Members (current and former)

Other WNE Alumni

|